PCBA test (English PCBA test) refers to the electrical conductivity of PCBA circuit board mounted with electronic components and the test based on input and output values. In the design of PCB circuit board, there is a numerical relationship between different test points, such as voltage and current. It needs to use professional test equipment or manual operation multimeter to test the test points, so as to verify whether the actual PCBA Board meets the design requirements. PCBA test is the key step to ensure the quality of production and delivery. According to the test points, procedures and test steps designed by customers, FCT test fixture is made, and then PCBA board is placed on FCT test rack to complete the test< br />

PCBA testing principle

Connect the test points on PCBA board through FCT test rack to form a complete channel, connect the computer and the burner, and upload the MCU program. MCU program will capture the user's input action (for example, long press the switch for 3 seconds), control the on-off of nearby circuit (for example, LED flashing) or drive the motor to rotate through calculation. By observing the voltage and current values between the test points on the FCT test stand, and verifying whether these input and output actions are consistent with the design, the test of the whole PCBA board is completed.

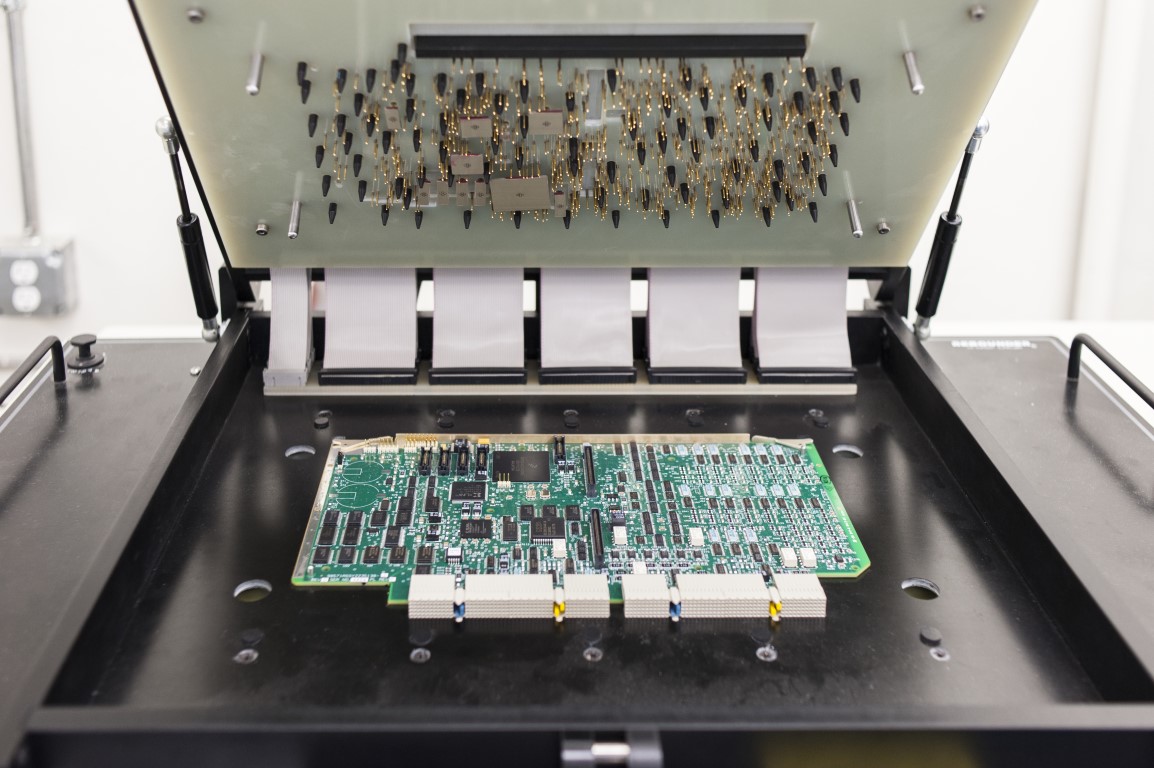

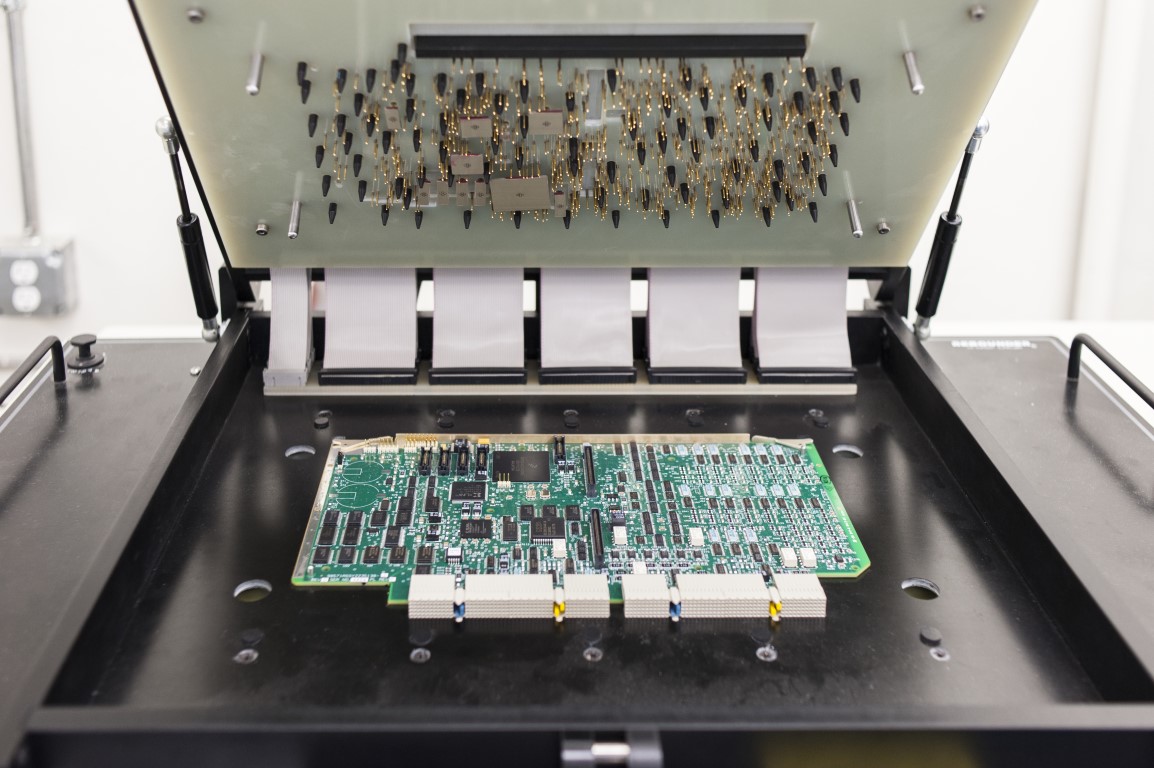

PCBA test stand

It is necessary to test a large number of PCBA boards, and the corresponding fixture is usually issued to assist the efficient completion. The principle of the test rack is to connect the test point of the test thimble and the PCB board. When it is powered on, the key data such as voltage and current in the circuit can be obtained and displayed on the display screen of the test rack, so as to achieve the purpose of rapid detection. When customers design PCB, engineers will consider their test plan, reserve PCB test points, and issue professional test documents or test plan to manufacturers. Our company can make PCBA test stand by itself (equipped with engraving machine and test stand assembly engineer).

Example: PCBA test plan of a foreign customer

The types of PCBA tests are as follows:

ICT (in circuit test): it mainly detects the voltage / current data of the test point after the PCB is powered on, and does not involve the test of function keys or input and output.

FCT (functional test) test: it is necessary to burn the MCU program to the program IC through the burning device (such as St link, JTAG), so as to realize the corresponding functional test. For example, after pressing the button, the LED light is on; Press the two buttons at the same time to restore the factory settings, etc. Of course, all the functions of the test can be carried out, must be based on the PCB welding OK and line conduction as the premise, otherwise it can not be realized.

Burn in test: simulate user input and output for a long time and periodically for PCBA board that has burned program and passed FCT, so as to test its durability and welding reliability. In special cases, PCBA board needs to be exposed to specific temperature and humidity environment.

PCBA testing is an essential part of the whole PCBA manufacturing supply chain. To control the quality from the final data results, PCBA testing must be considered and implemented in the standardized design and manufacturing management.