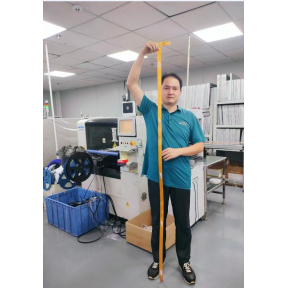

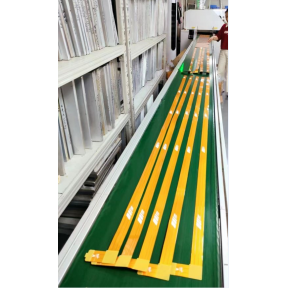

The decision to opt for oversized PCB manufacturing isn't taken lightly. These boards are chosen when smaller, standard-sized options can't meet the technical or spatial requirements of a project.

The decision to opt for oversized PCB manufacturing isn't taken lightly. These boards are chosen when smaller, standard-sized options can't meet the technical or spatial requirements of a project.

Nowadays, the hottest consumer application in MCPCB is LED. That’s because the dissipation of heat is getting more attention from the designer. The reason is that both lifespan and luminous decay of LED are all directly linked to the junction temperature of the LED. Moreover, the led junction temperature is also related to energy consumption. According to an experiment conducted by Cree, the time for luminous decay drop to 70% is 100 thousand hours if the temperature is kept at 65 Celsius. Many tests have proved that LED generates heat is because electricity input cannot completely transform to light but heat. The luminous efficiency of LED is about 100lm/W. The electricity-luminous conversion ratio is only between 20~30%. That means about 70% of current input turns into heat. By reducing heat generated, we can increase luminous efficiency and conserve energy.

.png)

Aluminum metal core PCB ※1~ 8 W/Mk High-thermal conductivity dielectric bonding material available. ※1L+A / 2L+A / 4L+A single side & Double side & Multi-layers.

Application

LED Backlight Module

Street Lighting & Signal Using High Power LEDs

General Lighting

Outdoor Lighting

Automotive Lighting

Power Conversion

Mortor Controlls

Military & Aerospace Field

Benefits of MCPCB

Utilize Surface Mount Technology

Very good heat-conducting and dissipating characteristics than regular PCB

By providing good thermal characteristics, it enhances the quality and lifespan of the product

Can be used to replace ceramic substrate with excellent mechanical durability

Product miniaturized through efficiency upgrade can save costs from hardware and assembly

Metal core PCB, MCPCB, is a general term of PCB in which traces are made on top of one layer of metal plate for improved heat transferring and...

.jpg)

.jpg)

.jpg)

.jpg)

Mobile:13326856492 Telephone:0755-84827607

Email:[email protected]