EMS (electronics manufacturing services) electronic manufacturing is a service process that makes product design concept into product. It needs to integrate electronic technology, supply chain, engineering process, production management and human resources, and has high professionalism. We provide customers with one-stop EMS electronic manufacturing services, including design, component procurement, PCB manufacturing, placement, plug-in, testing, assembly and other processes.

Design

Customers generally provide product design scheme, including schematic diagram, drawings, layout, MCU program, BOM, PCB gerbers, assembly SOP and other documents. We can also provide joint development services for customers, build prototypes according to product concepts, and then determine technical parameters, product structure and development cycle, so as to rapidly promote R & D and mass production.

Sample prototype

According to the design scheme, we can quickly make mold shell, PCB circuit board, purchase electronic components, and then carry out SMT chip, dip plug-in, PCBA test, three proofing paint spraying, finished product assembly, aging test and other core processes, so as to verify the reliability of the design, DFM manufacturability and so on.

Mold making

We have many years of cooperation in mold outsourcing factory, equipped with more than 20 injection molding machines, complete shell injection molding, oil injection, silk screen printing, pad printing, assembly, radium carving process capacity.

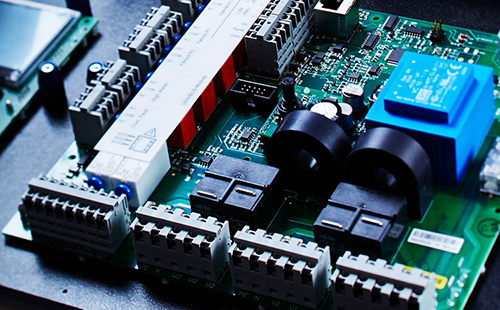

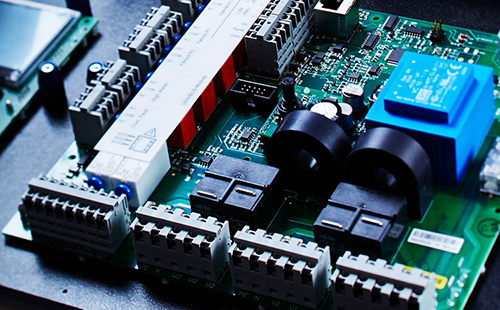

Circuit board making

The whole process operation of the factory, without any outsourcing process, effectively controls the quality, supports through hole PCB, FPC, HDI, blind hole, carbon film board, etc., with a monthly production capacity of 50000 square meters, TS16949 / UL / CE / RoHS / ISO9001 certification, standard flying pin test, test bench test, AOI (automatic optical inspection) and other appearance inspection.

Procurement of electronic components

It has a long-term and stable supply chain, and has established 5-10 years of cooperation with the original manufacturers and agents of IC, resistor, capacitor, inductor, connector, crystal oscillator, display screen, transformer, relay, diode and triode and other classified devices, and obtained the support of accounting period and technical after-sales. Our company establishes the SQE annual audit mechanism to evaluate all suppliers, so as to continuously ensure the supply capacity and quality of components.

SMT processing

Equipped with professional SMT processing and manufacturing team, high-speed SMT production line, dip plug-in production line, perfect AOI, ICT, FCT test process team, and assembly process conforming to ISO9001:2008 and ipc-a-610e class II electronic acceptance standards, we are able to undertake the task of mounting precision components (such as 0201 chip, BGA, pin IC, etc.).

PCBA test

PCBA test is the key step to ensure the quality of production and delivery. According to the test points, procedures and test steps designed by customers, FCT test fixture is made, and then PCBA board is placed on FCT test rack to complete the test. Our company can make PCBA test stand by itself, equipped with engraving machine and test stand assembly engineer.

Three proofing paint spraying

To meet the needs of customers for humidity, temperature, corrosivity and other harsh environment applications, our professional three proofing paint spraying production line is a fully automatic one-stop mode including spraying equipment, UV detection and baking.