LED 灯具设计

LED 灯具设计

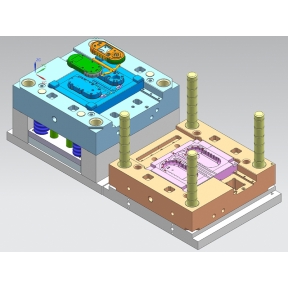

3D模具设计图

3D模具设计图

3D模具设计图

我们可以根据客户的样品数据进行3D输出,并制作2D模具布局图和3D模具设计图。

模具设计

模具设计

注塑模具设计是注塑过程中的一个关键要素,因为它在决定最终产品的质量和准确性方面发挥着重要作用。该过程包括为塑料材料创建模具,这些模具经过精确设计,可以创建所需产品的精确形状和尺寸。设计过程可能涉及几个阶段,从概念阶段开始,探索基本想法和草图,然后是详细的规划和工程设计,以最终确定设计。

模具设计与工程

模具设计与工程

模具设计与工程 注塑模具设计是注塑过程中的一个关键要素,因为它在决定最终产品的质量和准确性方面发挥着重要作用。该过程包括为塑料材料创建模具,这些模具经过精确设计,可以创建所需产品的精确形状和尺寸。设计过程可能涉及几个阶段,从概念阶段开始,探索基本想法和草图,然后是详细的规划和工程设计,以最终确定设计。

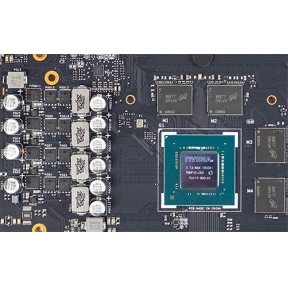

.png) PCB redesign

PCB redesign

PCB redesign. djt-e has done all optimizations and modifications djt-e could until the present moment. The current prototype (last picture) needs more hardware and firmware tests, maybe some further m...

.png) Electronics manufacturing service(EMS)

Electronics manufacturing service(EMS)

djt-e is committed to being a professional and trustworthy partner in Electronics manufacturing service(EMS), including turnkey electronic assembly and materials management services, to original equip...

.png) How to test the PCBA board?

How to test the PCBA board?

How to test the PCBA board? 1. PCBA board manual test Manual testing is to test directly by the vision and confirm the component mounting on PCB through vision and comparison. This technology is wide...

FUJI PICK AND PLACE

FUJI PICK AND PLACE

Printed Circuit Board Assembly Overview 100% 3D X-ray Inspection after SMT and at Final QA on every leadless part to ensure no shorts, opens, or voids are present Content 100% Inline AOI ensures no errors with parts placement, mis-alignment, mis-orientation, and solder joint defects 12 zone ovens with on-demand Liquid Nitrogen for 99.99% purity on solder joints Dual wave and Selective wave Soldering Machines 100% Inline Solder Paste Inspection First article QA Inspection done on every job Flying Probe Test Parametric Bench Test

生产视频链接分享

生产视频链接分享

1. https://v.youku.com/v_show/id_XNTgwMjM1NjA4OA==.html 2. https://v.youku.com/v_show/id_XNTExNzU2Mjk3Ng==.html 3. https://v.youku.com/v_show/id_XNTExNjY0OTI2MA==.html 4. https://v.youku.com/v_show/id...

EMS电子制造

EMS电子制造

EMS (Electronics Manufacturing Services)电子制造是将产品设计理念制造成产品的服务过程,需要集合电子技术、供应链、工程工艺、生产管理和人力资源,拥有较高的专业性。我们为客户提供一站式EMS电子制造服务,包括设计、元器件采购、PCB制造、贴片、插件、测试、组装等制程。 设计 客户一般提供产品的设计方案,包括原理图、Drawings、Lay...

PCB电路板加工

PCB电路板加工

PCB电路板快速打样 我们极度擅长为客户提供最短24小时的快速电路板打样服务。当您的公司需要快速电路板打样时,您只需要将文件交付给我们,即可在很短的时间内收到高质量的电路板,并且拥有十分诱人的价格竞争力。此外,针对您PCB电路板打样的过程中发现的设计问题,我们也会在试产报告中体现。所有的DFM可制造性检查和生产过程中的制程问题发现报告均是免费的。市场上很多PCB快速打样的公司是把十几款板子拼在...

电子元器件采购

电子元器件采购

为什么要外包电子元器件采购? 随着产业分工细化,越来越多的电子产品研发公司精简组织架构,将有限的资源配置在研发和销售这两个核心竞争力上,从而将繁琐的生产制造环节外包出去,在这种趋势下,势必会加大对于PCBA包工包料的需求。客户只需要提供设计文件,让电子制造商按照设计要求采购电子元器件和完成PCBA生产制造过程,这种包工包料的模式,节约客户自建物料采购检验仓储的人员成本和呆滞成本,从整体上看,反...

Printed Circuit Board Assembly Overview

Printed Circuit Board Assembly Overview

100% 3D X-ray Inspection after SMT and at Final QA on every leadless part to ensure no shorts, opens, or voids are present Content 100% Inline AOI ensures no errors with parts placement, mis-alignment, mis-orientation, and solder joint defects 12 zone ovens with on-demand Liquid Nitrogen for 99.99% purity on solder joints Dual wave and Selective wave Soldering Machines 100% Inline Solder Paste Inspection First article QA Inspection done on every job Flying Probe Test Parametric Bench Test

PCBA后焊3

PCBA后焊3

PCBA后焊2

PCBA后焊2

PCBA后焊1

PCBA后焊1

自动固晶机

自动固晶机

自动封胶机

自动封胶机