Process capability of dip plug-in processing

AOI of plug-in is used to detect the error, leakage and inversion of components, and strictly control the dip through rate

The skilled soldering hand with strict training can control the welding speed and quality

According to the status of the circuit board, the temporary storage area with independent identification around the pull wire: to be inserted, to be repaired, to be inspected by QC, defective products, to be inspected by QA, etc., to avoid mixed board

Strict IPQC and QA lot sampling standards to ensure the reliability of DIP processing

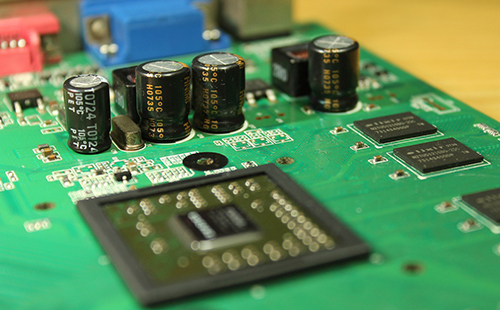

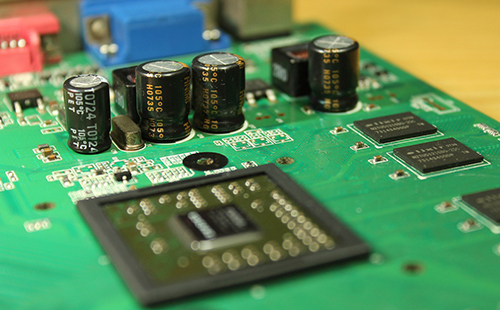

Dip plug in processing equipment

Plug in line x 2

Plug in AOI: check the bad items of plug-in components and solder joints

Wave soldering x 2 sets

Rear welding stay wire x 24 station

Washing machine x 1 set

Dip plug-in processing is a part of PCBA electronic processing process. There are more manual operations, which puts forward higher requirements for management. Through the implementation of a set of perfect quality management system (iso9001:2015, ISO13485, iatf16949) and equipped with constantly improving automation equipment (such as automatic plate splitter, automatic dispenser, automatic spot welder, etc.), fixtures, etc., our DIP processing service is highly consistent and reliable, and has won the praise of customers.