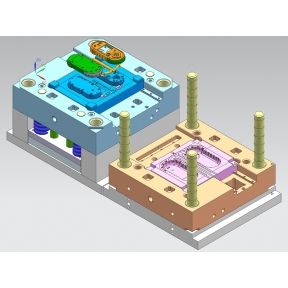

3D Design

3D Design

We can make 3D output according to the customer's samples data, and make 2D mold layout drawings and 3D mold design drawings.

LED Light

LED Light

Make 2D mold layout drawings and 3D mold design drawings.

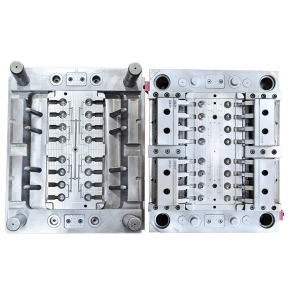

Mold Design

Mold Design

Mold Design & Engineering Injection mold design is a crucial element of the injection molding process, as it plays a significant role in determining the quality and accuracy of the final product. The process involves creating molds for plastic materials that are precisely engineered to create the exact shape and size of the product required. The design process can involve several stages, beginning with a concept phase where basic ideas and sketches are explored, followed by detailed planning and engineering to finalize the design. We can make 3D output according to the customer's samples data, and make 2D mold layout drawings and 3D mold design drawings.

Mold Design & Engineering

Mold Design & Engineering

Mold Design & Engineering Injection mold design is a crucial element of the injection molding process, as it plays a significant role in determining the quality and accuracy of the final product. The process involves creating molds for plastic materials that are precisely engineered to create the exact shape and size of the product required. The design process can involve several stages, beginning with a concept phase where basic ideas and sketches are explored, followed by detailed planning and engineering to finalize the design. We can make 3D output according to the customer's samples data, and make 2D mold layout drawings and 3D mold design drawings.

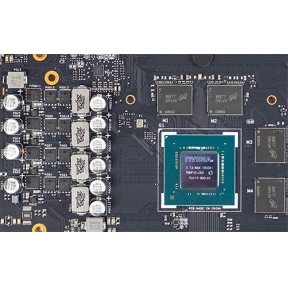

.png) PCB redesign

PCB redesign

PCB redesign. djt-e has done all optimizations and modifications djt-e could until the present moment. The current prototype (last picture) needs more hardware and firmware tests, maybe some further modifications in the project of the PCB, then can produce a batch of 100pcs for extensive tests and pre-compliance/EMC tests. If this project reaches expectations and goals, for me it will be like a s...

.png) Electronics manufacturing service(EMS)

Electronics manufacturing service(EMS)

djt-e is committed to being a professional and trustworthy partner in Electronics manufacturing service(EMS), including turnkey electronic assembly and materials management services, to original equipment manufacturers (OEMs) in the electronics industry. Below are our major business: 1. PCB, Flex-Rigid PCB, PCB Assembly, PCB Fabrication and PCB Layout from concept to volume manufacturing 2. Wire ...

.png) How to test the PCBA board?

How to test the PCBA board?

How to test the PCBA board? 1. PCBA board manual test Manual testing is to test directly by the vision and confirm the component mounting on PCB through vision and comparison. This technology is widely used. However, the large number and small components make this method more and more unsuitable. Moreover, some functional defects are not easy to be found, and the data is not easy to collect. In t...

FUJI PICK AND PLACE

FUJI PICK AND PLACE

Printed Circuit Board Assembly Overview 100% 3D X-ray Inspection after SMT and at Final QA on every leadless part to ensure no shorts, opens, or voids are present Content 100% Inline AOI ensures no errors with parts placement, mis-alignment, mis-orientation, and solder joint defects 12 zone ovens with on-demand Liquid Nitrogen for 99.99% purity on solder joints Dual wave and Selective wave Soldering Machines 100% Inline Solder Paste Inspection First article QA Inspection done on every job Flying Probe Test Parametric Bench Test

EMS Electronic Manufacturing

EMS Electronic Manufacturing

EMS (electronics manufacturing services) electronic manufacturing is a service process that makes product design concept into product. It needs to integrate electronic technology, supply chain, engineering process, production management and human resources, and has high professionalism. We provide customers with one-stop EMS electronic manufacturing services, including design, component procuremen...

PCB circuit board processing

PCB circuit board processing

Rapid proofing of PCBWe are extremely good at providing customers with the shortest 24 hours of fast circuit board proofing service. When your company needs fast circuit board proofing, you only need to deliver the documents to us, you can receive high-quality circuit boards in a very short time, and have a very attractive price competitiveness. In addition, we will also reflect the design problem...

Procurement of electronic components

Procurement of electronic components

Why outsourcing electronic components procurement?With the refinement of industrial division of labor, more and more electronic product R & D companies streamline organizational structure, allocate limited resources in the two core competitiveness of R & D and sales, so as to outsource the cumbersome production and manufacturing links. In this trend, it is bound to increase the demand for PCBA lab...

SMT chip processing

SMT chip processing

we provide customers with high-end SMT chip processing services, equipped with four automatic high-speed SMT chip production lines, automatic loading machine, automatic solder paste printing machine, SPI solder paste thickness detector, multi temperature zone reflow soldering, AOI optical testing equipment, X-ray inspection machine, baking machine, steel mesh cleaning machine, etc., and provide p...

Printed Circuit Board Assembly

Printed Circuit Board Assembly

100% 3D X-ray Inspection after SMT and at Final QA on every leadless part to ensure no shorts, opens, or voids are present Content 100% Inline AOI ensures no errors with parts placement, mis-alignment, mis-orientation, and solder joint defects 12 zone ovens with on-demand Liquid Nitrogen for 99.99% purity on solder joints Dual wave and Selective wave Soldering Machines 100% Inline Solder Paste Inspection First article QA Inspection done on every job Flying Probe Test Parametric Bench Test

PCBA post weld 3

PCBA post weld 3

PCBA post weld 2

PCBA post weld 2

PCBA postweld 1

PCBA postweld 1

Automatic solidification machine

Automatic solidification machine

Automatic sealing machine

Automatic sealing machine